Articles

Smart Concrete

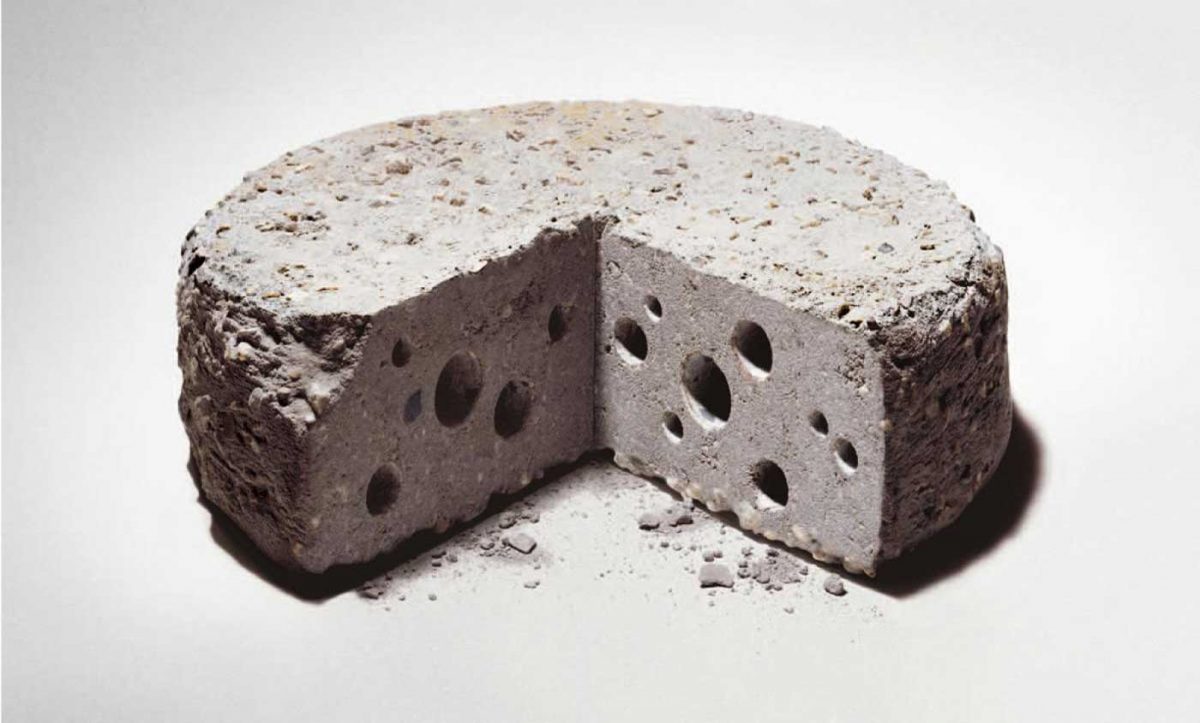

Concrete is the most widely used construction material because of its high compressive strength, relatively low cost etc. One adverse property of concrete is its sensitivity to crack formation as a consequence of its limited tensile strength.For that reason, concrete is mostly combined with steel reinforcement to carry the tensile loads. Although these rebars restrict the crack width, they are mostly not designed to completely prevent crack formation. Cracks endanger the durability of concrete structures as aggressive liquids and gasses may penetrate into the matrix along these cracks and cause damage. Consequently, cracks may grow wider and the reinforcement may be exposed to the environment. Once the reinforcement starts to corrode, total collapse of the structure may occur. Therefore, it seems obvious that inspection, maintenance and repair of concrete cracks are all indispensable. However, crack repair becomes difficult when cracks are not visible or accessible. Moreover, in Europe, costs related to repair works amount to half of the annual construction budget. In addition to the direct costs, also the indirect costs due to loss in productivity and occurrence of traffic jams carry a severe economic penalty. Accordingly, self-healing of cracked concrete would be highly beneficial. Self-healing is actually an old and well known phenomenon for concrete as it possesses some natural autogenous healing properties.However, autogenous healing is limited to small cracks, is only effective when water is available and is difficult to control. In 1969, self-healing properties were for the first time built-in inside polymeric materials.

Principle Of Smart Concrete

Concrete is a construction material that is used world-wide because of its first-rate properties. However, the drawback of this material is that it easily cracks due to its low tensile strength. It is a well-known fact that concrete structures are very susceptible to cracking which allows chemicals and water to enter and degrade the concrete, reducing the performance of the structure and also requires expensive maintenance in the form of repairs. In this paper, the following notable points regarding classification of bacteria, self-healing of cracks in concrete, chemical process for crack remediation, self-healing mechanism of bacteria, application of bacteria in construction field, Advantages and disadvantages of bacterial concrete etc., are observed and identified from the other research works. Cracking in the surface layer of concrete mainly reduces its durability, since cracks are responsible for the transport of liquids and gases that could potentially contain deleterious substances. On the other hand the concrete structures show some self-healing capacity, i.e. the ability to heal or seal freshly formed micro-cracks

Advantages:

- Helpful in filling of cracks in concrete.

- Helpful to reduce leakage of residential building.

- Helps to reduce permeability in concrete.

- Helpful to reduce corrosion of reinforced concrete.

- It increases durability of concrete.

MATERIALS:

1.Cement –Ordinary Portland cement of grade 53 available in local market is used in the investigation. The cement used has been tested for various properties as per IS: 4031-1988 and found to be confirming to various specifications of IS: 12269-1987 having specific gravity of 3.0.

2.Coarse Aggregate –Crushed granite angular aggregate of size 20 mm nominal size from local source having specific gravity of 2.71 is used as coarse aggregate.

3.Fine Aggregate –Natural river sand having specific gravity of 2.60 and confirming to IS-383 zone II is used.

4.Water –Locally available portable water confirming to standards specified in IS 456-2000 is used.

5.Microorganisms –Any of the following bacteria may be used for the process:

Contact Info

Iran office phone

+98 21 44906869

Canada office phone

+1 (647) 402 7774

info@dalahoobetonsaee.com

Iran office address

Ayatolah Kashani St., Sazman Barnameh North St., Tehran, Iran

Factory address

No 11/1, First Shavrivar Alley, Tavoon Blv, Asheri St, 11km Tehran-Karaj Highway, Tehran, Iran

Canada office address

509-7191 Yonge Street, Thornhill, Ontario, L3T 0C4, Canada

Copyright 2021 – Dalahoo Beton Saee company. All rights reserved.